As a child, Emily Baker loved to make paper versions of things: cameras, a spaceship cockpit, buildings for a town in outer space.

It was a habit that stuck. Years later, studying architecture in graduate school at the Cranbrook Academy of Art in Michigan, she was playing around with some paper and scissors. It was 2010, and the school was about to buy a CNC plasma cutter, a computer-controlled machine capable of cutting lines into sheets of steel. As she thought about how she might experiment with it, she made a striking discovery.

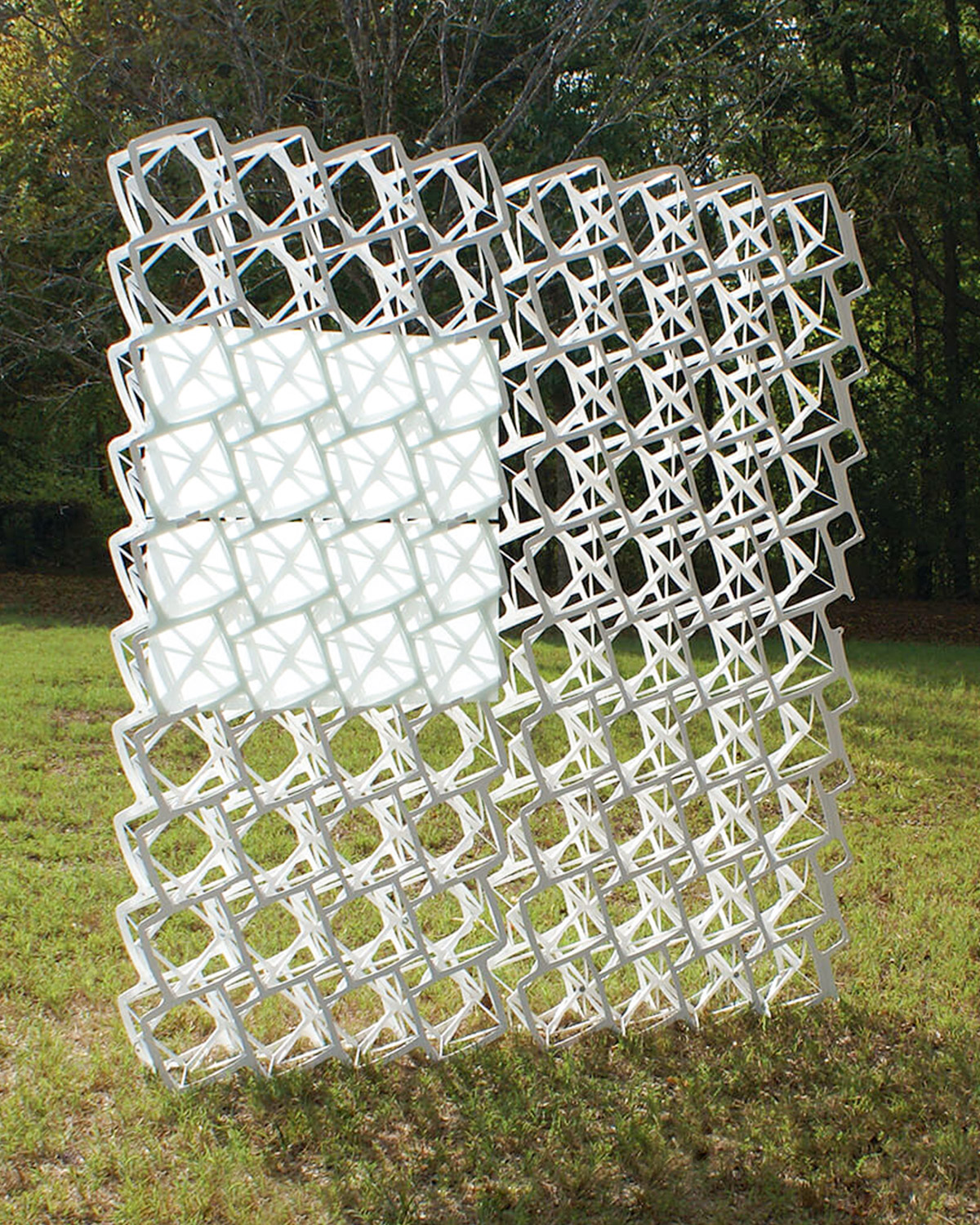

By making a series of cuts and folds in a sheet of paper, Baker found she could produce two planes connected by a complex set of thin strips. Without the need for any adhesive like glue or tape, this pattern created a surface that was thick but lightweight. Baker named her creation Spin-Valence. Structural tests later showed that an individual tile made this way, and rendered in steel, can bear more than a thousand times its own weight.

In chemistry, spin valence is a theory dealing with molecular behavior. Baker didn’t know of the existing term when she named her own invention—“It was a total accident,” she says. But diagrams related to chemical spin valence theory, she says, do “seem to have a network of patterns that are very similar to the tilings I’m working with.”

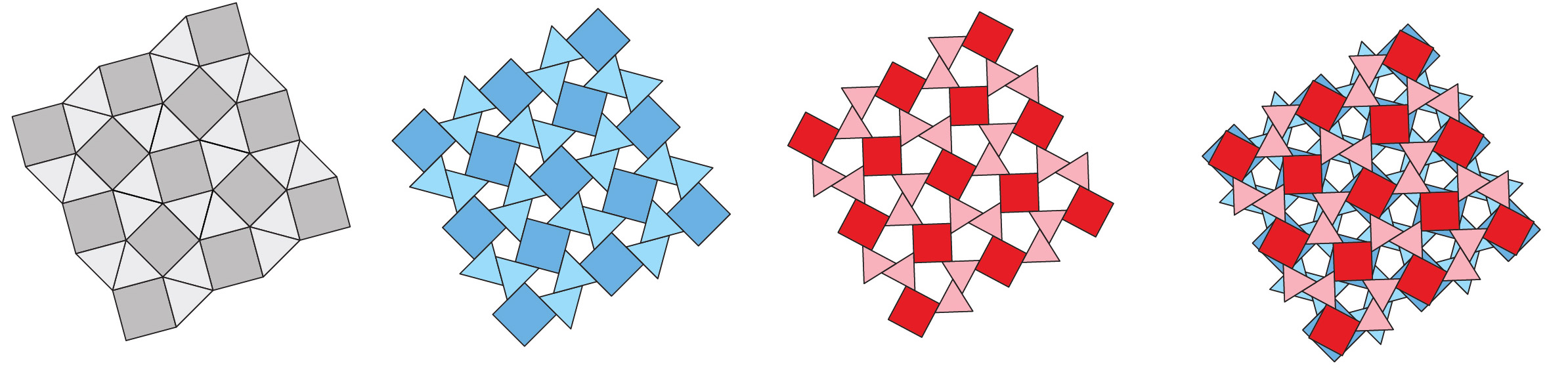

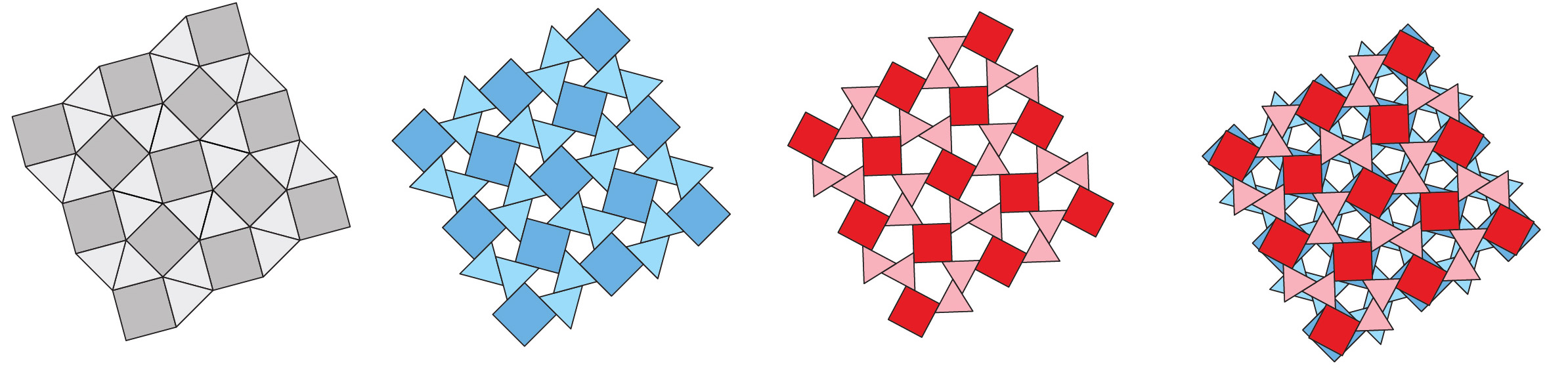

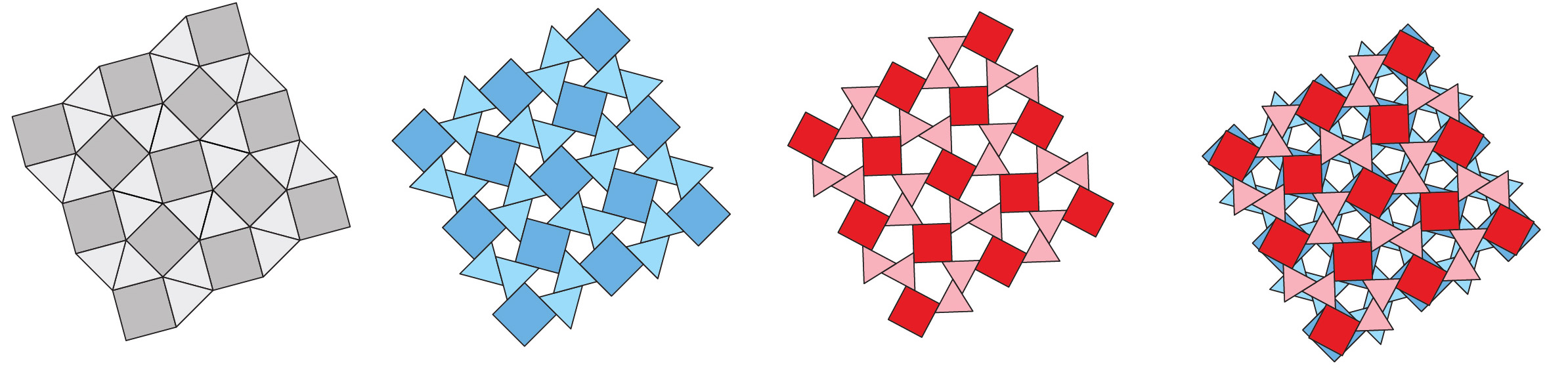

Soon, Baker began experimenting with linking individual tiles together to produce a larger plane. There are perhaps thousands of geometric cutting patterns that can create these multiplane structures, and she has so far discovered only some of them. Certain patterns are stronger than others, and some are better at making curved planes.

Baker uses software to explore each pattern type but continues to work with cut paper to model possibilities. The Form Finding Lab at Princeton is now testing various tiles under tension and compression loads, and the results have already proved incredibly strong.

Baker is also exploring ways to use Spin-Valence in architecture and design. She envisions using the technique to make shelters or bridges that are easier to transport and assemble following a natural disaster, or to create lightweight structures that could be packed with supplies for missions to outer space. (Closer to home, her mother has begun passing along ideas to her quilting group; the designs bear a strong resemblance to quilt patterns.)

“What I find most exciting about the system is the way it adds stiffness to something that was previously very flexible,” says Isabel Moreira de Oliveira, a PhD candidate in civil engineering at Princeton, who is writing her dissertation on Spin-Valence and testing which shapes work best for specific applications. “It entirely changes the behavior of something without adding material to it.” Plus, she adds, “you can ship this flat. The assembly information is embedded in how it’s cut.” This could help reduce transportation costs and lower carbon emissions generated from shipping.

Baker grew up in Alabama and Arkansas, the daughter of a librarian and a chemical engineer at Eastman Kodak. Everybody in the family made things by hand—her mother taught her how to sew, and her father taught her how to work with wood. In high school, she took some classes in the school’s agricultural program, including welding, where she had a particularly supportive teacher. “I’ll tell you who the best two welders in the class are gonna be right now,” she recalls him saying, as he pointed at her and the only other female student. And, she says, “it was true. We picked it up a little faster than the guys. It was really empowering.”

Baker went on to study chemical engineering at the University of Arkansas in Fayetteville before she switched to architecture, drawn to the more tactile work. After five years at a small architecture firm in Jackson, Mississippi, she enrolled at Cranbrook, where she sensed she would have the space and tools to experiment. She now teaches in the architecture program at the University of Arkansas.

No doubt her experience in high school welding class aided in a more recent collaboration. Together with her UA colleague Edmund Harriss, an assistant professor of mathematics and art, she has developed Zip-Form—a system for welding and bending two sheets of steel together to make complex 3D curves using low-cost tools and easily learned skills.

As a process, it is “a physical manifestation of integrating differential properties of the curve,” Harriss says. “The way the mathematical theory links to manufacturing process in Zip-Form is incredibly clean and elegant.” He explains that Baker’s willingness to engage seriously with the mathematics sets her apart from other architects he has worked with: “I think often people get intimidated by the mathematics and try to fall back on their expertise to say where the mathematics isn’t working.” Baker wasn’t like that.

Like Spin-Valence, Zip-Form has potential applications in construction. Shortly after developing the technique, Baker met Mohamed Ismail, now an assistant professor of architecture at the University of Virginia, who was then a PhD student at MIT. He was working on low-cost, low-carbon structural systems for housing in developing countries. When Ismail learned that Baker and Harris had found a way to make complex 3D structures out of flat sheets, his mind immediately went to concrete. A system like this, he says, is “exactly the kind of thing that is necessary when you’re trying to build complex concrete formwork [molds to pour the concrete into] in places where you don’t have a robotic arm or 3D printer.”

In a project they worked on together, Baker and Ismail used Zip-Form to create a mold for a 16-foot prototype curved beam that’s more environmentally sustainable than a traditional beam, reducing the total carbon emissions associated with resource extraction, production, transport and other stages in the typical life cycle of a beam by 40%.

While most concrete buildings use vastly more material than is structurally necessary, curved beams save concrete by using material only where it is needed to bear a structural load. Concrete is responsible for approximately 8% of total global carbon emissions, but it is also desperately needed to build housing, especially in places like India and Africa, where the population is forecast to grow rapidly in the next 20 years. Zip-Form demands more labor than more automated processes, but the equipment it uses is more affordable.

Ismail and Baker are now working with a fabrication company in Kenya to demonstrate to real estate developers and an African housing nonprofit that this technology is competitive on price with traditional methods, and thus has a key role to play in affordable construction. The construction industry in the US can be mind-numbingly slow to adopt new techniques, Baker and Ismail both say, but they believe Zip-Form can easily be brought into building projects, using tools and materials that are already available.

Zip-Form has creative potential, too. Danielle Hatch, an artist known for large-scale fabric installations, is using the system to make a public sculpture in Arkansas inspired by the movement of ribbons on the dancers she saw at a Hispanic cultural festival. “How could I evoke that sense of lightness and play, with metal?” she wondered. Zip-Form allowed her to make steel that she describes as “lyrical.”

Baker has been inspired by the work of R. Buckminster Fuller, the polymath known for popularizing the geodesic dome—and for turning his mind to everything from affordable housing and transportation to renewable energy. She has studied his story closely, especially reflecting on the gaps between the broad scope of his thought—which often sought to revolutionize entire systems—and the limited real-world changes that resulted from his ideas. “Is there something I should have learned from his life and experience?” she wonders.

Like Fuller, whose work extended far beyond architecture to consider the ways people relate to one another and to materials, Baker doesn’t think just about physical forms but about how people build, live, and manufacture—and the hierarchies that determine who does what. She thinks of architecture as always being in conversation with the body of the builder. A brick, she points out, is an excellent example because it’s the perfect size for a worker to hold while slathering it with mortar. Baker wants the tools she creates to be just as practical.

Sofi Thanhauser is a writer, artist, and musician based in Brooklyn, New York, and the author of Worn: A People’s History of Clothing.

Post a Comment